The type of plastic anisotropy usually desired in sheet metal forming is that the sheet is isotropic in the plane and has an increased strength in the thickness direction which is nor mally referred to as normal anisotropy.

Plastic anisotropy in sheet metal forming.

The lankford coefficient also called lankford value r value or plastic strain ratio is a measure of the plastic anisotropy of a rolled sheet metal.

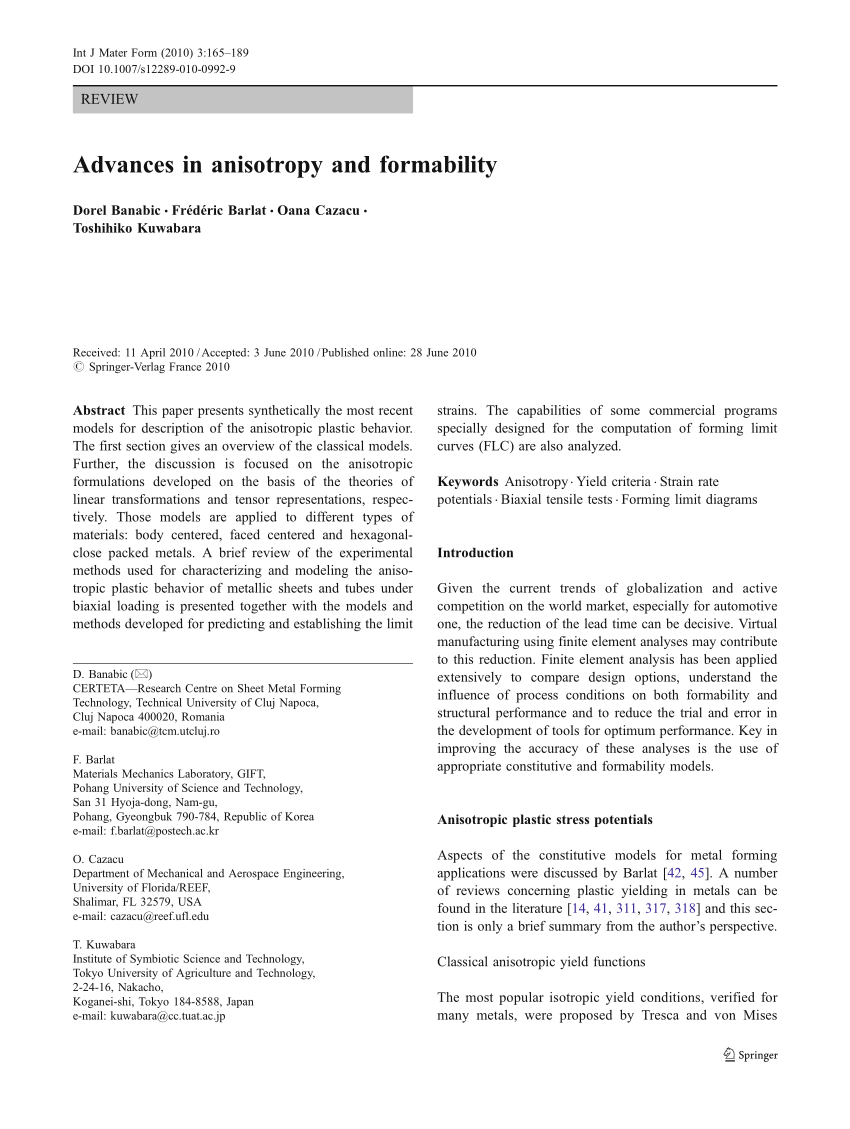

A profound survey is given of literature about yield criteria for anisotropic materials up to most recent developments and the calculation of forming limits of anisotropic sheet me tal.

A general elasto plastic finite element formulation based on incremental deformation theory for planar anisotropy and its application to sheet metal forming int.

More often however the type of plastic anisotropy is characterized by different strengths in different directions in the plane of the sheet as well which is called planar anisotropy.

A large chapter is devoted to formability testing both for bulk metal and sheet metal forming.

Advances in anisotropy of plastic behaviour and formability of sheet metals.

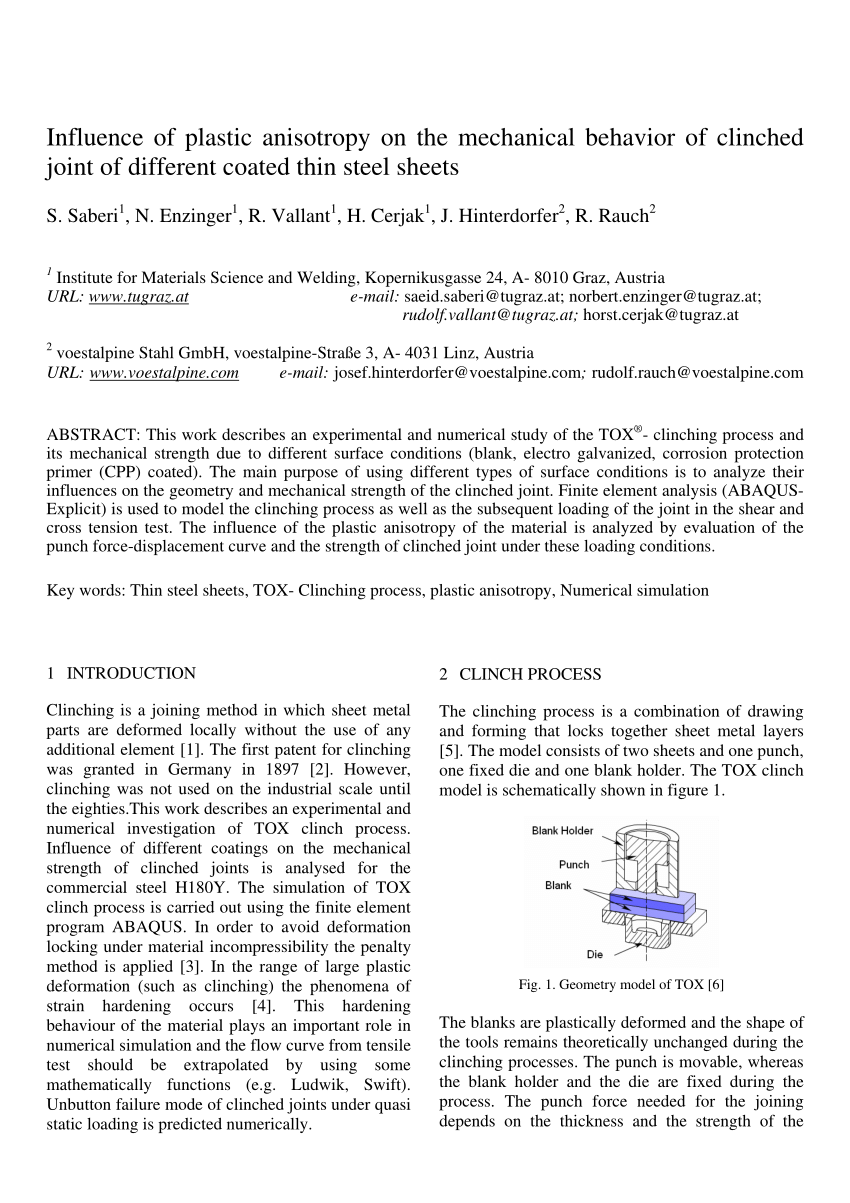

It is shown that the neglect of the anisotropy in the simulations leads to inaccurate results.

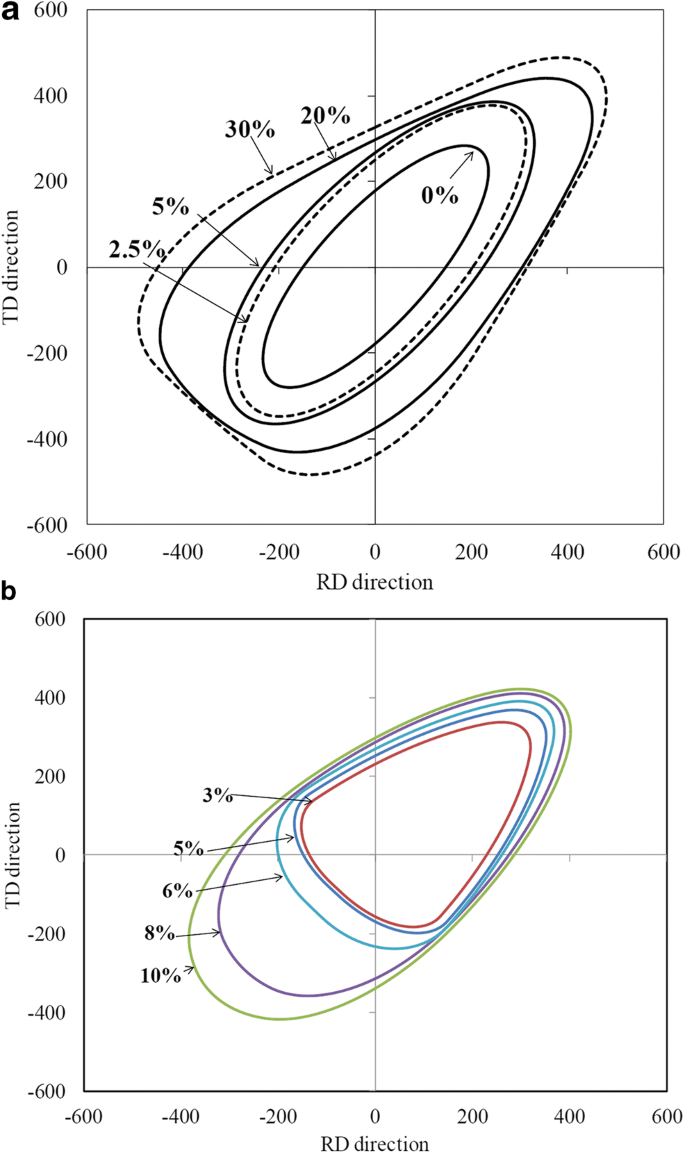

A stress points forming contours of plastic work of aluminum alloy sheet 6016 o compared with the yield loci.

The analysis is based on the deformation theory and hill s theory of plastic anisotropy.

If r 1 then the sheet is of course isotropic 9 22 2015 39 40.

A general elasto plastic finite element formulation based on incremental deformation theory for planar anisotropy and its application to sheet metal forming int.

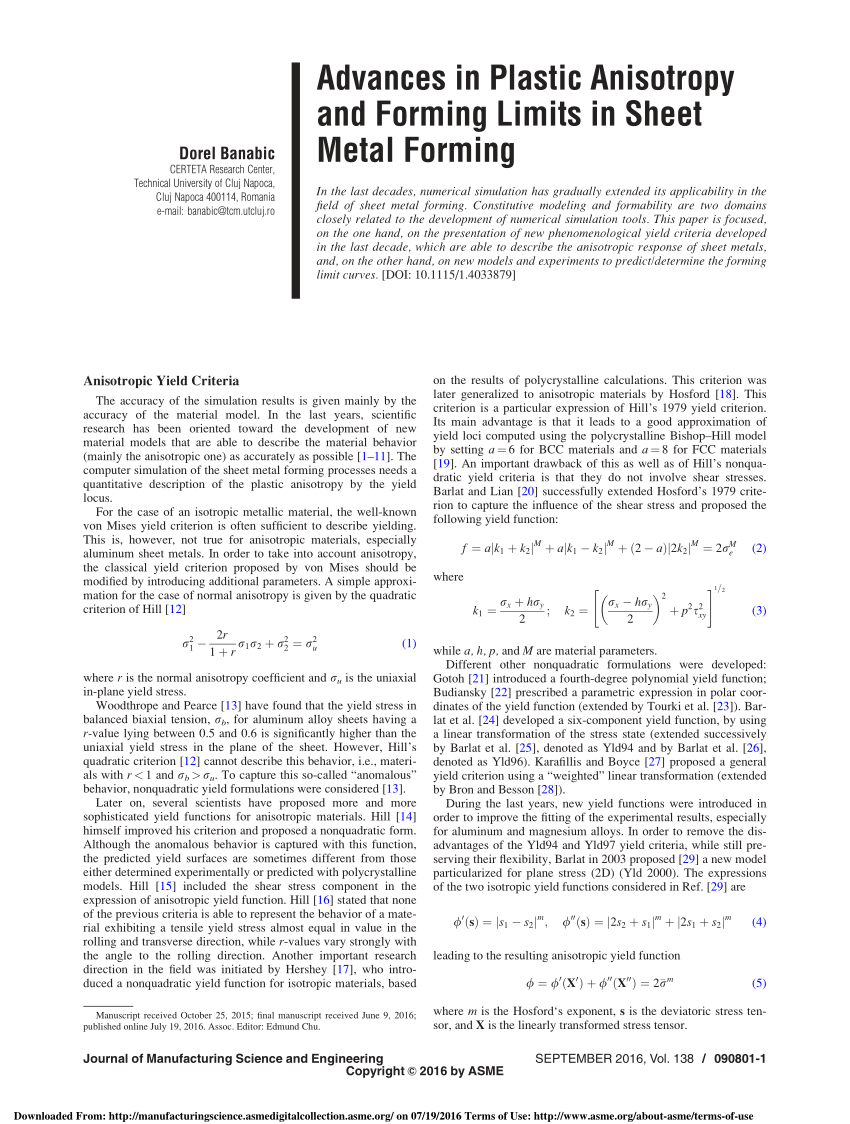

The computer simulation of the sheet metal forming processes needs a quantitative description of the plastic anisotropy by the yield locus.

Plast 15 1 1999 pp.

Planar anisotropy if by performing experiments on the sheet it is found that the measured r value is unchanged with orientation the sheet is said to have planar anisotropy.

The numerical results are compared to experiments.

Numerical analysis is carried out in order to investigate the influence of plastic anisotropy on sheet metal forming processes such as stretching and deep drawing.

For the first time testing methods for plastic anisotropy of round bars and tubes are included.

Finally the effect of plastic anisotropy on the puckering behavior in the spherical cup deep drawing process is investigated.

Memorandumului 28 400114 cluj napoca romania.

Anisotropic one as accurately as possible 1 11.